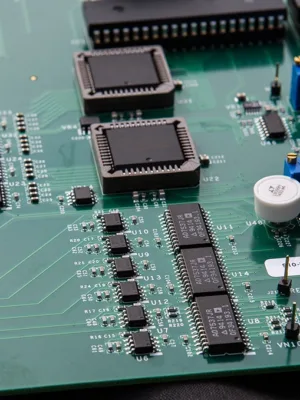

PCB Assembly

SEM has a team of highly qualified PCB designers who…

SEM has a team of highly qualified PCB designers who…

Our facility has state-of-the-art equipment capable of tackling any manufacturing

SEM offers in-house X-ray inspection and BGA rework.

SEM has put a robust quality management and process evaluation…

SEM maintains a quality operation streamlined for efficient production and…

SEM offers upgrade and ECO implementation services during the assembly…

SMT AssemblyThrough the use of modern, flexible, and well-maintained surface…